|

|

Post by micro on Oct 11, 2016 8:10:02 GMT -5

Microbrush first off you are doing an amazing job. I would be more apt to bore my holes if I had the option to use a mandrel like you have. I think both boring and reaming can be accurate. I have to recut a mandrel every time that I remove mine for a different processes so I chose to use a reamer. I can setup and ream several pucks in a few minutes then move to the lathe where I can cut a set of usable wheels in approximately fifteen minutes. Just my thoughts with my equipment. I think we are both producing excellent wheels with totally different processes. It sure feels good knowing we can produce our own parts and be competitive with the big dogs! Good Response King. Great point about having to make a new mandrel if you remove it. I think that is how most people go about the process. That might be why people come up with other ways to leave their set up on the lathe. Thanks also for bringing the reamer to the attention of everyone. One other way you might be able to keep your mandrel is if you make it from a hexagon stock piece and then mark your jaws and stock piece so you can place it back the same way with repeatability. I bought some stock for that purpose a while back, but have not tried it yet. I read about it somewhere and thought it was an interesting concept. Yes, making my own parts is my favorite part about the hobby. I like to learn new things and this hobby has provided that in droves. I never would have thought the little cars would ever be so complex. |

|

|

|

Post by micro on Oct 11, 2016 11:18:02 GMT -5

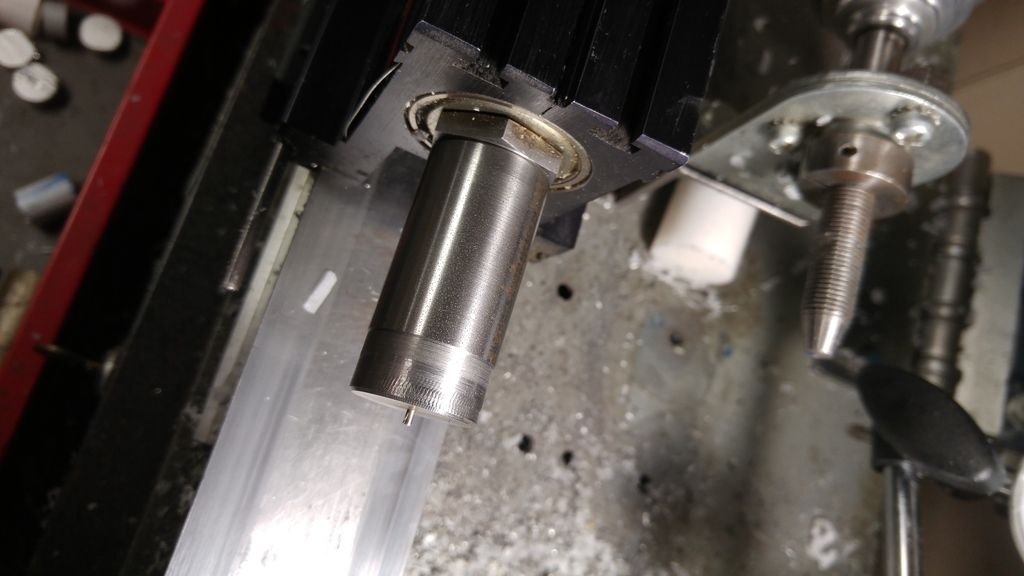

This is how the blank starts off. I drilled and tapped my own hole. |

|

|

|

Post by micro on Oct 11, 2016 11:23:08 GMT -5

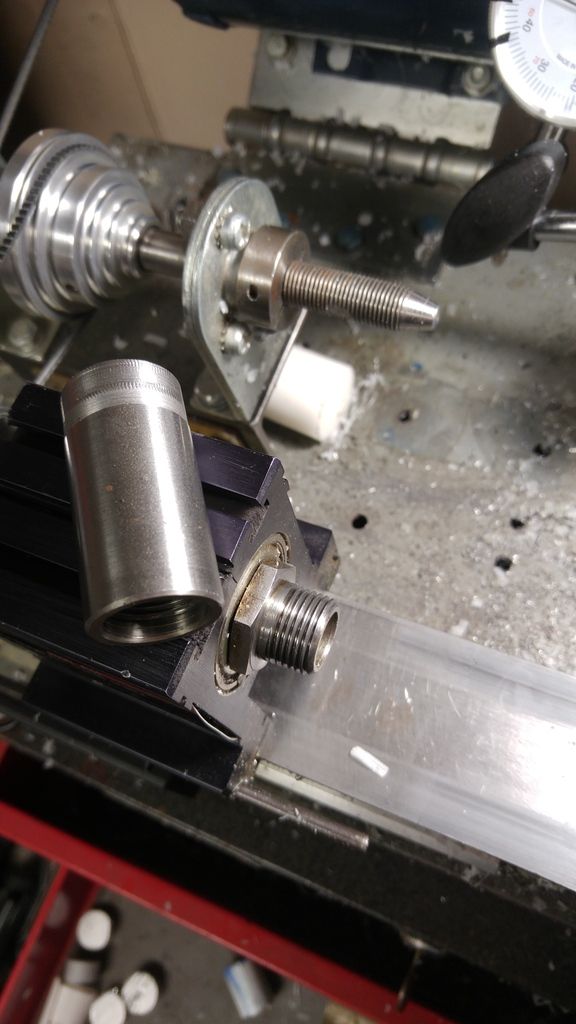

The piece off of the spindle. |

|

|

|

Post by Vitamin K on Oct 11, 2016 21:02:13 GMT -5

Just wanna say this thread is awesome. I have no idea what I'm looking at, but it looks really cool and makes me feel wholly inadequate. Haha Makes me wish I could afford a lathe, that's for sure. |

|

|

|

Post by micro on Oct 24, 2016 8:58:06 GMT -5

Ok, I alluded to using hexagon stock in a three jaw chuck and that might allow for accurate replacement of a part back in the Jaws. Well, I decided to try it since I had the piece of hexagon stock.  First thing is to cut it. It is made out of aluminum. I read that you can cut it with a normal chop saw. I had a replacement blade just in case it didn't work. I was a little skeptical to say the least. |

|

|

|

Post by micro on Oct 24, 2016 8:59:13 GMT -5

What do you know it worked! |

|

|

|

Post by micro on Oct 24, 2016 9:00:25 GMT -5

Here is a better look at the stock piece. The small piece has already been cleaned up. How did I do that? |

|

|

|

Post by micro on Oct 24, 2016 9:01:42 GMT -5

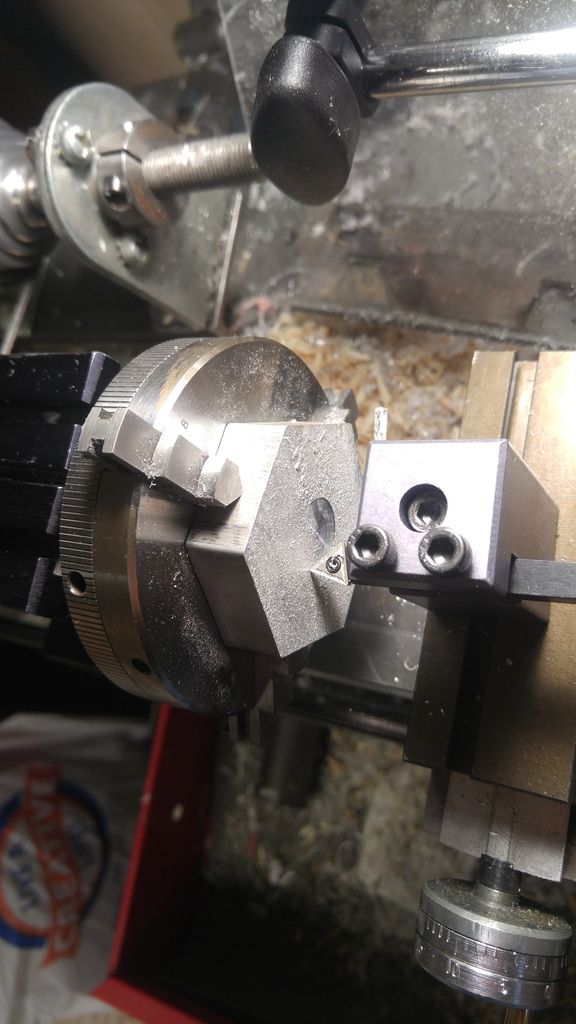

Place it in on the lathe and start to face it off? Is that the correct term? |

|

|

|

Post by micro on Oct 24, 2016 9:02:38 GMT -5

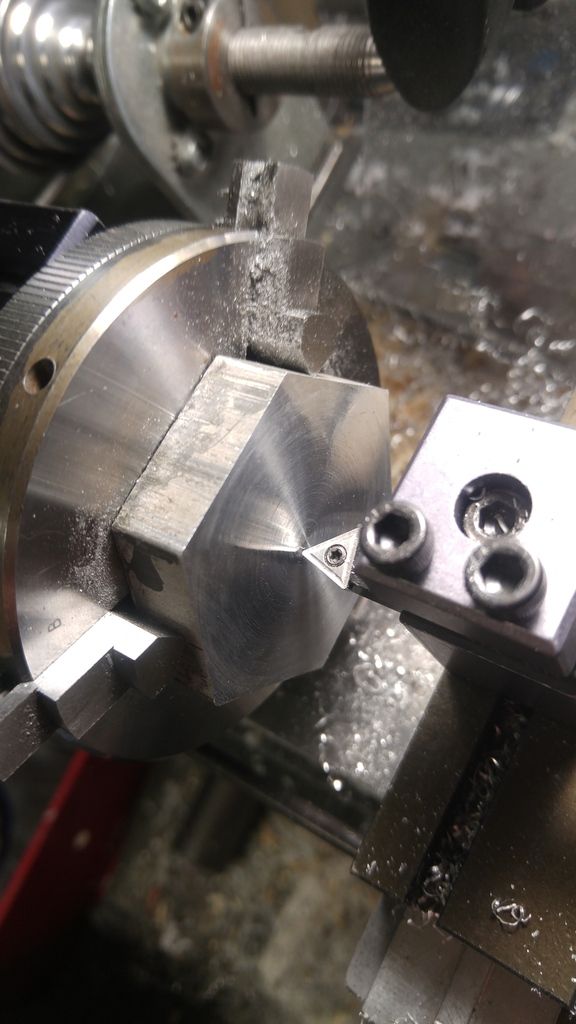

Then it starts to look nice. Flip it around and do the other side. |

|

|

|

Post by micro on Oct 24, 2016 9:05:17 GMT -5

What should we make with this piece? How about a pot chuck like Jim made. Bore a hole and mark the sides to correspond with the jaws of the three jaw chuck. |

|

|

|

Post by micro on Oct 24, 2016 9:42:17 GMT -5

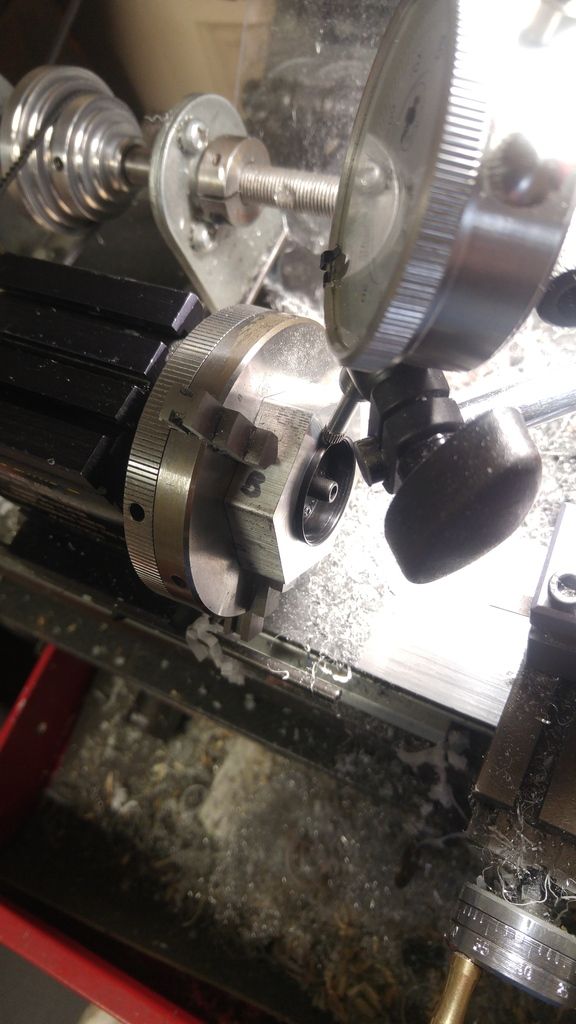

The wheel in the "pot chuck". I removed the "pot chuck" and reinserted and don't get run out. I also removed the 3 jaw chuck and put it back on and then put the "Pot Chuck" back on and still looks good to me. Interesting! I guess you'll have to take my word for it. I have extra stock if someone else wants to give it a go let me know if you can't find your own Hexagonal piece. |

|

|

|

Post by Vitamin K on Oct 24, 2016 10:52:31 GMT -5

I removed the "pot chuck" and reinserted and don't get run out. I also removed the 3 jaw chuck and put it back on and then put the "Pot Chuck" back on and still looks good to me. Interesting! I guess you'll have to take my word for it. I have extra stock if someone else wants to give it a go let me know if you can't find your own Hexagonal piece. Fascinating! So the hex piece lets you remove/insert the piece into the 3-jaw without introducing detectable error? I wonder if it would be possible to turn a hex base with round mandrel for holding a wheel, so that you didn't have to turn a new one each time you changed the setup. |

|

|

|

Post by The Zeebzob on Oct 24, 2016 11:01:25 GMT -5

I removed the "pot chuck" and reinserted and don't get run out. I also removed the 3 jaw chuck and put it back on and then put the "Pot Chuck" back on and still looks good to me. Interesting! I guess you'll have to take my word for it. I have extra stock if someone else wants to give it a go let me know if you can't find your own Hexagonal piece. Fascinating! So the hex piece lets you remove/insert the piece into the 3-jaw without introducing detectable error? I wonder if it would be possible to turn a hex base with round mandrel for holding a wheel, so that you didn't have to turn a new one each time you changed the setup. It could certainly be done. But anytime you use a 3 jaw chuck, you can introduce run out when changing the setup. You need independent jaws to truly get rid of it. This would get you close, though. Whether or not the tolerance is close enough to dissuade you form investing in a 4 jaw would up to you. |

|

|

|

Post by Vitamin K on Oct 24, 2016 12:11:10 GMT -5

Fascinating! So the hex piece lets you remove/insert the piece into the 3-jaw without introducing detectable error? I wonder if it would be possible to turn a hex base with round mandrel for holding a wheel, so that you didn't have to turn a new one each time you changed the setup. It could certainly be done. But anytime you use a 3 jaw chuck, you can introduce run out when changing the setup. You need independent jaws to truly get rid of it. This would get you close, though. Whether or not the tolerance is close enough to dissuade you form investing in a 4 jaw would up to you. I guess it depends on where the tolerances lie. If it's like, +/- .0005", I would consider that negligible. If it's introducing .001" or more of runout, that's another matter. Of course, I'm just a poor bum with no lathe (yet), so it's all purely speculative from my end.  |

|

|

|

Post by micro on Oct 24, 2016 12:32:55 GMT -5

I removed the "pot chuck" and reinserted and don't get run out. I also removed the 3 jaw chuck and put it back on and then put the "Pot Chuck" back on and still looks good to me. Interesting! I guess you'll have to take my word for it. I have extra stock if someone else wants to give it a go let me know if you can't find your own Hexagonal piece. Fascinating! So the hex piece lets you remove/insert the piece into the 3-jaw without introducing detectable error? I wonder if it would be possible to turn a hex base with round mandrel for holding a wheel, so that you didn't have to turn a new one each time you changed the setup.That's what I'm insinuating. I took the Pot chuck on and off about 5 times and it was good each time. I didn't need to fiddle with it. |

|