|

|

Post by micro on Oct 7, 2016 22:07:56 GMT -5

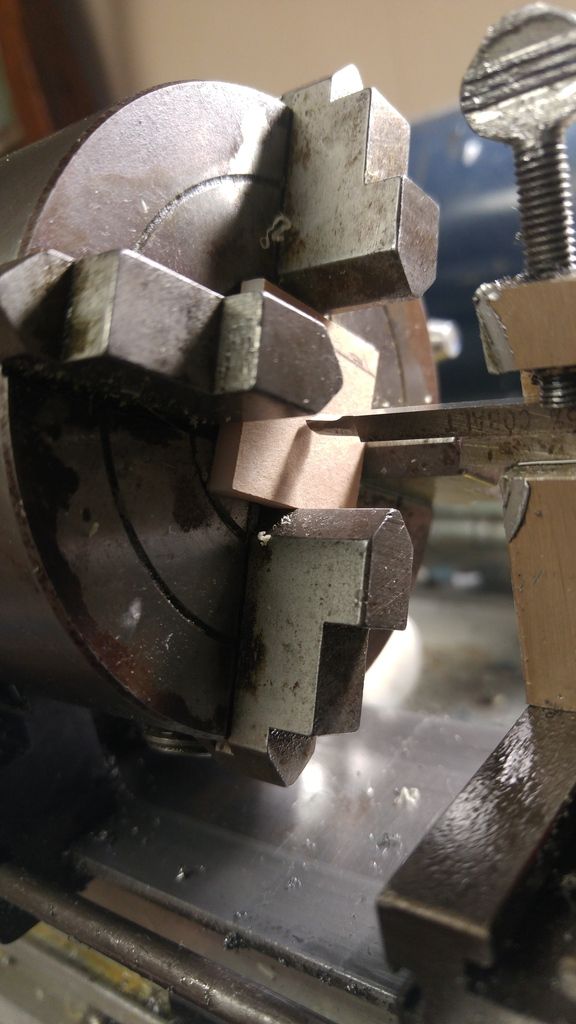

Start off with a square wheel. Make a micro-boring bar to bore a hole to about 0.155 |

|

|

|

Post by micro on Oct 7, 2016 22:09:31 GMT -5

Can Verify with a gauge pin. |

|

|

|

Post by Admin on Oct 7, 2016 22:12:18 GMT -5

Oh Snap! I love this forum already!

|

|

|

|

Post by micro on Oct 7, 2016 22:13:57 GMT -5

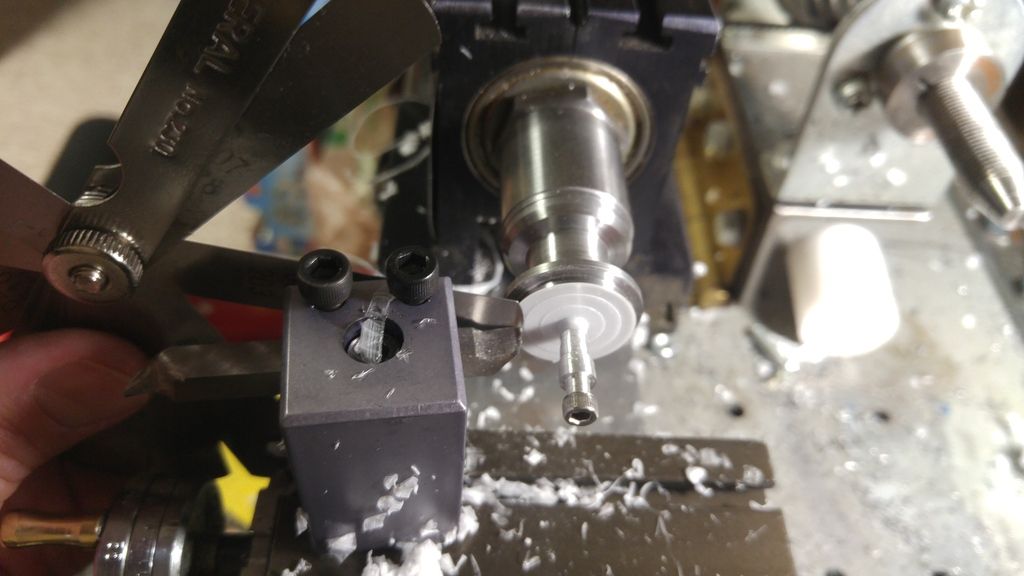

Make a custom fixture. I use a mandrel that attaches directly to the spindle. I can take it off and on and not have any run out. I have a Taig Lathe and can buy these blanks directly from the company. It is easy to do and easy to switch out the mandrel to a 3 or 4 jaw or any thing you would like and then switch it back again. |

|

|

|

Post by micro on Oct 7, 2016 22:14:28 GMT -5

If you want to know more let me know and I will keep posting.

|

|

|

|

Post by Admin on Oct 7, 2016 22:19:41 GMT -5

Yes! Of course I do!

Nice clear photos.

Thanks! ... and welcome to my forum Jeff.

|

|

|

|

Post by micro on Oct 7, 2016 22:23:08 GMT -5

Put your square piece of acrylic on the fixture and make it round. You can increase the RPM's for this step and it will take less than a minute. If you prefer you can purchase a premade round puck. |

|

|

|

Post by micro on Oct 7, 2016 22:24:08 GMT -5

A round wheel. |

|

|

|

Post by micro on Oct 7, 2016 22:25:54 GMT -5

You can make the various thickness of the wheel to your liking. |

|

|

|

Post by micro on Oct 7, 2016 22:28:47 GMT -5

I use a feeler gauge to get the various thicknesses to the sizes I prefer. You can also use a feeler gauge to help get/tease the wheel off of the fixture. |

|

|

|

Post by micro on Oct 8, 2016 21:19:37 GMT -5

From What I read boring a hole is the most accurate method. I am for sure not a machinist, but I am really astonished that I seem to be the only one who bores a hole. What am I missing? Drilling and reaming might be easier I suppose? Is that the only reason? I can make the hole with the boring bit and then open to size. I don't have to switch to a drill bit and then a reamer. Thoughts? Comments? Criticisms?

|

|

|

|

Post by gravitymafia on Oct 9, 2016 8:54:47 GMT -5

Thanks for the close ups!!

|

|

|

|

Post by Admin on Oct 9, 2016 18:56:34 GMT -5

Good stuff MB!

Have you had a chance to try out Acrylite SG?

This is the sign grade acrylic... and it comes in way more colors than the standard acrylic.

|

|

|

|

Post by micro on Oct 10, 2016 8:07:25 GMT -5

Good stuff MB! Have you had a chance to try out Acrylite SG? This is the sign grade acrylic... and it comes in way more colors than the standard acrylic. No, I have not been able to find SG locally and have not ordered it online. It seems like you can get a sample box of 4"x4" I might try and order that at some point. It does seem to have all the colors of the rainbow. |

|

|

|

Post by kingracing on Oct 10, 2016 17:30:36 GMT -5

Microbrush first off you are doing an amazing job. I would be more apt to bore my holes if I had the option to use a mandrel like you have. I think both boring and reaming can be accurate. I have to recut a mandrel every time that I remove mine for a different processes so I chose to use a reamer.

I can setup and ream several pucks in a few minutes then move to the lathe where I can cut a set of usable wheels in approximately fifteen minutes.

Just my thoughts with my equipment. I think we are both producing excellent wheels with totally different processes.

It sure feels good knowing we can produce our own parts and be competitive with the big dogs!

|

|